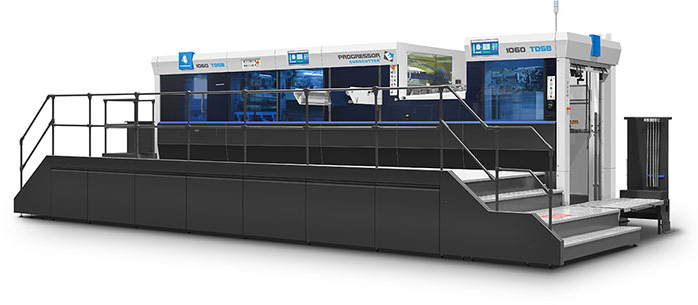

Flatbed Die Cutter PROGRESSOR 1060 TDSB

Equipped with stripper, blanking and double cam gripper bar unit:

- Feeder: Using suction heads, this unit transports sheets from the pile to the machine in-feed

- In-feed: Takes control of each individual sheet and registers it to the cutting tools using mechanical and dynamic registration

- Platen section: This is the heart of the machine, bringing the cutting die and cutting plate together under pressure. Held between them, the sheet of substrate may be die-cut, creased or embossed, depending on the application and substrate

- Stripping section: Internal waste, and sometimes side and rear trim, is removed using an upper stripping tool, central stripping board, and, in some tooling arrangements, lower stripping pins

- Inline blanking section with continuous pile lowering and constant batch compression ensure perfectly stacked piles in non-stop operation

- Delivery: The delivery aligns the sheets and creates a pile of full sheets.

- With high-speed double cam gripper bar unit

- max. sheet size: 1060 x 760 mm

| PROGRESSOR 1060D | mm | inches |

| Max. sheet size | 1060 x 760 | 41.7 x 29.9 |

| Min. sheet size | 400 x 350 | 15.74 x 13.77 |

| Max. die-cutting size | 1045 x 745 | 41.14 x 29.33 |

| Die size | 1075 x 765 | 42.32 x 30.11 |

| Cutting plate | 4 + 1 | 0.15 + 0.039 |

| Gripper margin | 7 – 17 | 0.27 – 0.67 |

| Carton board g/m² | 90 – 2.000 | |

| Carton board | 0.1 – 3 | 0.0004 – 0.11 |

| Corrugated board | <= 4 | <= 0.157 |

| Max. cutting force in t | 350 | |

| Max. die-cutting speed in sheets / hour | 7500 | |

| Feeder pile height (incl. pallet) | 1800 | 70.86 |

| Delivery pile height (incl. pallet) | 1400 | 55.11 |

| Overall machine size (L x W x H) | 9800 x 6000 x 2700 | 385.82 x 236.22 x 106.29 |

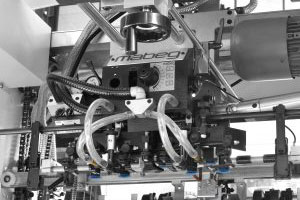

Progressor Mabeg feederhead

Progressor cutting chase pneum. locksystem

Progressor double cam gripper bar

Progressor cutting chase changer

Progressor stripping and blanking section

Progressor waste removal conveyor